5. Adhesive

6. Magnetic Signs

7. Flexible Type 2 bracket

To access the complete technical sheet, please go page Technical Sheets or Downloads

- Aluminium floor profile which has been specifically designed to be laid on uneven floor surfaces so that escape route boundaries can be clearly identified in an emergency situation and/or in the event of power failure.

- The low profile strips are supplied with an anti-slip photoluminescent (phosphorescent) polycarbonate top surface with the aluminium profile edges consisting of fine blades along their full length which enhance the floor strip’s anti-slip properties even in the event of oil or lubricant spillage.

- An Aluminium frame can be the perfect sign accessory to give a standard photoluminescent (phosphorescent) PVC sign a desirable, aesthetically pleasing finish.

- It has a discreet and elegant design and is manufactured using high quality materials.

- It allows for connection between the sign and the wall and its visual impact does not conflict with the sign resulting in perfect harmony between the three elements (wall – frame – sign).

To access the complete technical sheet, please go page Technical Sheets or Downloads

The Everlux Adhesive provides the ideal solution when installing signs to a variety of surfaces including those that are uneven, rough or irregular.

Main characteristics: To access the complete technical sheet, please go page Technical Sheets or Downloads

« return

6. Magnetic Signs

- All type 1 signs can be supplied with a magnetic finish which will allow for secure adhesion to all suitable metallic surfaces – this can be applied to all sign sizes.

- The magnetic finish is comprised of a rubber and ferrite compound which is applied to the rear surface of the signs.

- The magnetic finish offers an alternative solution when installing signs in a variety of applications, including plant rooms, storage facilities and industrial areas. They are also ideal for mounting on metal stands or frames or can be used as temporary signage either indoors or outdoors.

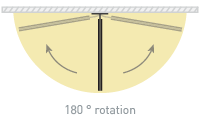

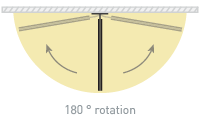

7. Flexible Type 2 bracket

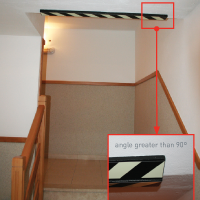

- This bracket features a plastic, flexible strip which has been developed to allow the sign to move sideways within a 180Ǿ radius without breaking and then return to its correct starting position following any impact or collision.

- The bracket has been specifically developed for installation in areas where the likelihood of a collision or impact may be increased. As such, it is ideal for areas where forklift trucks operate and cargo is distributed such as warehouses, factories, supermarkets and goods yards.

- The Flexible Type 2 bracket´s durable design ensures the sign is resistant to collision, impact and vandalism.

- The Flexible Type 2 bracket can also be fixed to the ceiling.

To access the complete technical sheet, please go page Technical Sheets or Downloads

Alternative solutions for fixing Type 3 suspended signs to accommodate differing ceiling types: Circular self-adhesive hanging buttons Square clips "S" shape hanging hooks Double hook hanging hooks Double hook extendable hanging hooks Ceiling to sign cable systems with fixings (available in 750 mm or 1200 mm lengths)

|